An innovative process paves the way for a new generation of photovoltaic panel assembly processes

CEA-Liten develops lightweight composite photovoltaic panels for various applications, including solar mobility. Their laboratories, on the INES site, have equipped themselves with a thermocompression press featuring an induction heating system. This equipment, LIT™ RAPID SOLAR, developed in partnership with Roctool, offers new and promising features.

Temperature and pressure conditions that open up new possibilities for photovoltaic module materials. The LIT™ RAPID SOLAR makes it possible to work at much higher temperatures than the lamination equipment normally used for assembling photovoltaic panels. It also ensures cooling in the same chamber, without breaking the applied pressure. These temperature and pressure conditions enable the use of new thermoplastic polymer materials and polymer-matrix composites for the encapsulation step in the module assembly. These materials offer exciting new opportunities and could in particular facilitate the recycling of PV modules, a major issue in this field.

Access to complex 3D formats. The tooling is interchangeable according to the needs of the application: it can be used to achieve flat formats, as well as curved or complex 3D shapes.

The features of LIT™ RAPID SOLAR make the difference in photovoltaic panels compared to the standard lamination process:

-

Process temperature up to 260°C, compared with 180°C

-

Applied pressure > 6 bar, compared with 1 bar.

Pre-qualification of this new process in a photovoltaic module assembly environment. Two photovoltaic panels, one made using a standard process, and the other using the LIT™ Rapid Solar process, passed 100 thermal cycles (-40°C to +85°C) and were tested under high humidity conditions (85°C and 85% relative humidity). Tests have shown that the two modules have equivalent performance, enabling this new process to be pre-qualified in a photovoltaic panel assembly environment!

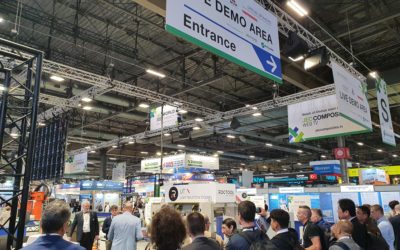

- Assembly equipment LIT™ RAPID SOLAR, developed in partnership with Roctool.

Credit CEA Laurence GODARD

-