JEC WORLD APPLICATION SPORT & LEISURE

CRTC gives second life to aerospace scrap prepreg

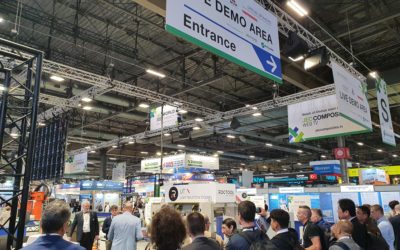

> Booth: Hall 6 – R39

The Composite Recycling Technology Center in Port Angeles, WA, is repurposing scrap carbon prepreg that has typically been landfilled.

The CRTC’s mission is to transform scrap previously considered waste material into new products contributing to a complete recycle solution. CRTC moved into a purpose-built

facility in August 2016 and has launched its first product using recovered aerospace scrap from Toray Composites America (TCA): a pickleball paddle (serving one of the fastest growing sports in America).

The ultralight, quiet paddle benefits from both material form and cost reduction, and will be commercially available in Q1 2017.

Using this product for strategic development of rapid compression moulding, CRTC is scaling into transportation and infrastructure applications to use greater volumes

of scrap prepreg.

CRTC is working with TCA and partners on an IACMI project for automotive composites. Fast cycle times (6 minutes) have been demonstrated with excellent quality using scrap prepreg. Several new products for 2017 are in development with a compression moulding approach.

To produce these, CRTC is acquiring three presses from Wabash/MPI, a 200kW RocTool induction heating system, a 3 x 2m waterjet by Flow Corporation, a second Wisconsin oven for larger

infrastructure projects, and a 5-axis 3 x 1.5 x 1.2m DMS machining cell. These capabilities provide volume manufacturing capabilities to 500 tonnes per year

displaced from landfill by 2022.