GEKA Roctool technology lifts the aesthetics and quality of beauty packaging

Article from Premium Beauty News

Beauty application expert GEKA has introduced its Roctool Heat & Cool Technology, an induction molding method that produces precise, detailed and glossy packaging for applicators. This new process conserves resources, sustainably delivering stunning surface designs without visual defects.

Attractive packaging is essential to convey brand identity and catch consumer attention – especially for beauty products like mascara. To achieve stand-out surface finishes and effects on applicators, beauty brands often use a combination of injection molding, lacquering and metallization. However, these processes can be resource intensive and produce flaws in the final product.

Roctool overcomes these limitations by incorporating an induction network into the mold surface, which heats the mold for optimal material flow and superior surface finish. Suitable for use with standard plastics or GEKA’s sustainable post-consumer resin (PCR)-based products, Roctool’s technology eliminates the need for subsequent decoration, saving time and resources.

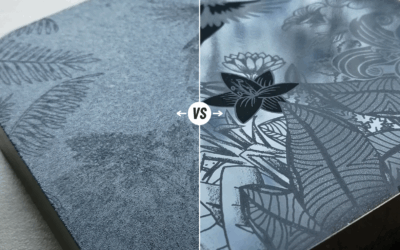

With better material flow, quality issues typically associated with injection molding such as sink marks, visible weld lines and defects are eliminated. Unlike other processes, the precise surface replication of Roctool means reduced rejects, less waste and no reworking.

Roctool’s technology produces glossy finishes and intense black, while the optimized molding process ensures that complex holographic effects and intricate 3D structures can be incorporated. Recessed and raised reliefs are also possible, which combined with detailed textures, provide customers with complete artistic license to create unique, eye-catching packaging.