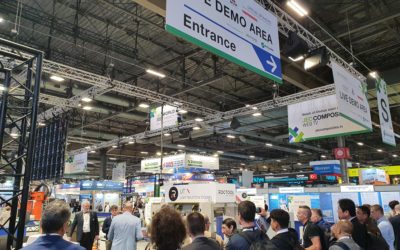

Roctool, from engineering expert to brand partner.

With a strong experience in engineering applied to various industries (carmaking, high-tech, consumer goods), Roctool is consolidating its legitimacy in the beauty packaging space. More than a supplier of cutting-edge technology, the company is accompanying brands thanks to its expertise in materials and transformation processes to find the best compromise between design, material and process.

We remember Roctool’s entry into the beauty world a few years ago. This important step for the company was in line with the ecological transition of packaging. Brands and manufacturers quickly perceived the economic and sustainability benefits of Roctool’s technology, notably when it comes to recycled materials.

Eco-molding, Roctool’s signature service

Thanks to its technological innovation involving induction during the injection phase and its knowledge of materials, Roctool is benefiting from its expertise and its experience to accompany beauty players in the development of their packaging. Roctool’s eco-molding initiative ensures a sustainable compromise between the choice of materials, the anticipation of textures and the definition of processes. This triple expertise is justified right from the product design stage. It accelerates the ecodesign approach.

Selecting the right material

Roctool’s HD Plastics database catalogs a multitude of traditional and new-generation resins. Each has been the subject of industrial tests allowing the identification of optimum parameters in the Roctool cycle (injection pressure, CO2 emission…) when compared with conventional molding. This library is constantly being enriched thanks to sourcing partnerships with materials suppliers, constituting a precious resource in defining the design of a part (format, wall thickness, complex forms…) due to the anticipation of the material’s behavior during injection. Roctool is equipped with a laser and injection laboratory that allows it to carry out a variety of different tests with partners and customers.

Revealing the material and limiting secondary processes

Thanks to the use of heat during the injection phase, the laser texturization of the molds allows the sublimation of the material and the obtention of a finished surface with spectacular results, including matt or high-shine, velvet touch and frosted effect finishes, for example. Roctool’s solution thus alleviates the need for certain secondary decoration steps, thereby reducing the product’s carbon footprint, notably when used with recycled materials.