Beaumont’s headquarters in Erie, Pennsylvania will now serve as Roctool’s North American Technology Demonstration and Trial Center.

ERIE, PA – Beaumont and Roctool, two technology leaders in the plastic injection molding industry, are teaming up to provide organizations with the opportunity to evaluate and learn more about Roctool’s heating and cooling technology. Beaumont’s headquarters in Erie, Pennsylvania will now serve as Roctool’s North American Technology Demonstration and Trial Center.

“We are excited about the opportunity to showcase Roctool’s advanced heating and cooling technology along with our already robust collection of industry technologies and solutions at our headquarters,” stated Alex Beaumont, Vice President at Beaumont. “Our mission at Beaumont is to improve our industry as a whole and to do this we need to continue to align ourselves with companies pushing the envelope to do so. We see Roctool as one of those companies and we look forward to seeing what we can do together.”

Mathieu Boulanger, Roctool’s CEO, added “we are incredibly happy to team up with Beaumont. This partnership is critical for Roctool as Beaumont is a key player in the world of injection molding with great technical skills. With this combined effort, we can now offer a top-notch molding environment to both our current and new customers, including demonstration, trial capabilities, and additional engineering services.”

Beaumont and Roctool will be collaborating on a variety of projects including utilizing Beaumont’s in-house material characterization resources to feed the simulation of Roctool systems. This will enable them to provide not only the quickest but also the most accurate simulation results possible. On top of that, combining two extraordinarily strong process development teams to bring the simulation results to fruition will ensure the delivery of a fully optimized production system for nearly any application.

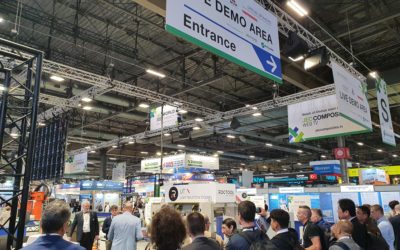

Companies with interest will have the opportunity to come to Beaumont and see Roctool’s capabilities running live. A fleet of molds is currently available for material characterization and immediate trial needs. In the future the site will also host industry-focused open houses to help companies further evaluate not only Roctool but also many other cutting-edge technologies and solutions Beaumont has created or aligned themselves with.

To learn more about Beaumont robust portfolio of engineering and manufacturing services for the injection molding industry, visit www.beaumontinc.com