Wednesday, October 19, 2022

Roctool presents its ECO-MOLDING™ initiative at K-2022 with 2 live demonstrations

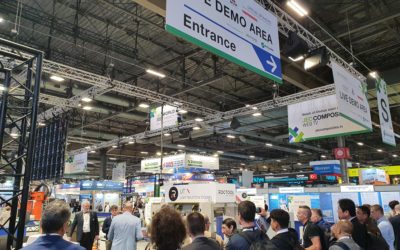

Roctool presents 2 Live molding demonstrations on 2 stands, showcasing Roctool’s latest initiative “ECO-MOLDING™”, combining innovative textures, recycled materials & Roctool state of the art heat and cool technology.

-

Live demonstrations on Roctool booth Hall 15, C41

-

Live demonstration on ENGEL booth Hall 15, C58

-

Roctool will also showcase multiple applications including Automotive, Beauty, Consumer Goods & Electronic applications.

-

Live Demonstration of a 2-Cavity mold with inter-changeable inserts on the Roctool booth Hall 15, C41:

This live demonstration on Roctool stand features an injection molding machine CX110-380 from KraussMaffei, Roctool’s longstanding show partner, 25kW & 50kW air cooled generators, that are user friendly, compact and lightweight, ideal for small parts and a micro thermoregulator which are all designed for the Roctool process.

Roctool will be running sessions during the 8-day show, using various materials and inserts with different textures and effects.

The Roctool technology demonstrates the exceptional mold replication directly onto the part surface to reach uncharted territories of design and functionality. Every visitor can experience the enhanced surface quality versus conventional molding with fast cycle times. Some of the unique innovative textures are realized by Standex Engraving in collaboration with Roctool using different types of resins.

Many Roctool experts will attend the show to discuss with visitors how the Roctool technology can help thickness reduction, surface defects removal, molding recycled resins, material flow extension or again reducing injection pressure.

Live Demonstration of a high-quality, thin wall housing part made with recycled materials:

Roctool ECO-MOLDING™ initiative is highlighted on the ENGEL (Austria) stand, using an e-mac 465/160 injection molding machine. The parts being produced are made from post-consumer recycled plastics from Lavergne (Canada). The unique surface textures were laser engraved by Standex (Italy), Moldetipo (Portugal) built the mold with INCOE (USA) providing the hot runner system. Roctool technology allows to mold an ultra-thin wall housing without surface defects.

A real team effort to bring this live demonstration to life for the K-2022.

Thin wall housing made out of post-consumer recycled plastics

Roctool technology is pushing the boundaries of plastic processing, entering new

design possibilities, reaching sustainable goals with best-in-class molding

performance.

About Roctool : Founded in 2000, Roctool is a technology and manufacturing solutions provider offering engineering services and systems. The Roctool induction process, perfectly adapted to plastic injection and compression molding, is available in many configurations to meet industrial requirements. Roctool’s research and development team is constantly adapting its technologies to new materials. Roctool is the leader in heat and cool technologies, and offers HDPlastics™ to plastic molders, Light

Induction Tooling technology – LIT™ to suppliers of composite parts and Induction Dual Heating technology – IDH™ for complete molding solutions. The processes developed by Roctool are used in production by leading brands in innovative sectors such as automotive, aerospace, beauty, consumer products and electronics. They offer many advantages, including reduced cycle times, excellent surface quality, weight and performance savings, which allows manufacturers to reduce the overall cost of the parts produced. Roctool is listed on the Euronext Growth market in Paris. Its headquarters and R&D center are located at Le Bourget du Lac (France). Roctool also has offices and platforms in North America, Japan, and China. www.roctool.com

Link to Press release in English

Link to Press release in French

Link to Press release in German

Link to Press release in Italian