Presentation of lightweight, 3D and eco-friendly solar panels at JEC and Intersolar

Roctool (Euronext Growth – FR0010523167 – ALROC), specialists in mold heating and cooling technologies for plastics and composites, will exclusively present the latest 100% thermoplastic molded solar panels at major international trade shows:

- JEC World – Paris from 03 to 05 May 2022

- INTERSOLAR – Munich from 11 to 13 May 2022.

In the course of a partnership with CEA, Roctool developed its Light Induction Tooling – LIT™ technology in the field of solar energy, thus named LIT” Rapid Solar “.

For the record, the ambitious objective of this program is to demonstrate the feasibility of a solar panel with a breakthrough process to allow:

- specific shapes and applications, such as the roof or the hood of a car

- fast cycle times, in the range of less than 15 minutes

- adaptability to future large-scale applications of over 3 m².

To propose a new, industrial technology:

- high speed

- flexible in terms of temperature control

- 100% European origin

- compatible with new advanced solar cell technologies.

And with a reduced environmental impact, including:

- low energy consumption per manufactured part

- can be used with 100% thermoplastic high-performance materials ––

- solutions compatible with 100% recyclable finished parts.

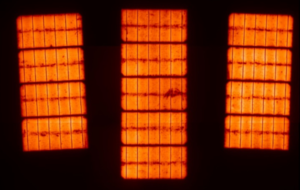

Since the beginning of 2022, a series of small-scale automotive hoods have been produced at Roctool SA’s technical center in Le Bourget-du-Lac, in collaboration with the CEA at the INES (notably for materials, components, and solar processes as well as solar panel tests).

Photo: Electroluminescence test after shaping, carried out at the CEA at the INES, demonstrating the proper functioning of the cells after shaping into photovoltaic panels

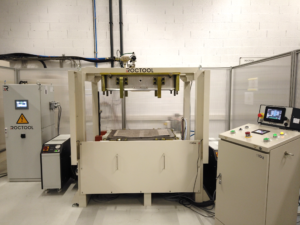

Photo 3: LIT equipment available at the Roctool SA test center

This innovation is maintained since June 2021 within the framework of the EasyPOC program, which is supported by the Auvergne-Rhône-Alpes region, in cooperation with the CEA. This first important milestone, obtained in collaboration with the CEA, is very promising for the development of new lightweight, eco-designed solar panels, but also for future applications where photovoltaic technologies can be exploited, such as the automotive industry.

“Our work, which was carried out in 10 months within the framework of the regional partnership between the Roctool teams and those of the CEA at the INES, has demonstrated cutting-edge know-how linked to the manufacture of innovative photovoltaic modules with a low environmental footprint. These new renewable energy markets are a real development opportunity for Roctool to satisfy an exponential demand at the European level in the solar field. The numerous initiatives supported by Europe will put forward our technology to meet the energy challenges of today and tomorrow. This project is clearly in line with Roctool’s development strategy and roadmap for the next few years,” says Matt Boulanger, CEO of Roctool.

Anis Jouini, Head of the CEA’s Solar Technologies Department at INES, says: “Solar energy is a constantly evolving field. We must therefore constantly innovate. At the CEA’s Liten Institute, the first European research center entirely dedicated to the energy transition, we are helping to develop new-generation solar cells and modules. We have all the assets in Europe to build this industrial sector of photovoltaic solar energy and to become the leader in this strategic sector, which has a bright future with many jobs at stake.”

Based on these very promising results, Roctool now aims to continue and strengthen its partnership with the CEA at INES in the solar field. The exhibition of the EasyPOC demonstrator at the next JEC WORLD and INTERSOLAR Munich shows will allow the consortium to exchange with industrialists in view of new application projects.

About Roctool: www.roctool.com

Founded in 2000, Roctool is a technology and manufacturing solutions provider offering engineering services and systems. The Roctool induction process, perfectly adapted to plastic injection and compression molding, is available in many configurations to meet industrial requirements. Roctool’s research and development team is constantly adapting its technologies to new materials, particularly metals. Roctool is the leader in heat and cool technologies, and today offers HDPlastics™ to plastic molders, Light Induction Tooling technology – LIT™ to suppliers of composite parts and Induction Dual Heating technology – IDH™ for complete molding solutions. The processes developed by Roctool are used in production by leading brands in innovative sectors such as automotive, aerospace, consumer products and electronics. They offer many advantages, including reduced cycle times, excellent surface quality, weight and performance savings, which allows manufacturers to reduce the overall cost of the parts produced. Roctool is listed on the Euronext Growth market in Paris. Its headquarters and R&D center are located at Le Bourget du Lac (France). Roctool also has offices and platforms in North America, China, Japan, Taiwan and Germany.

About EasyPOC :

The EasyPOC program aims to secure a high-tech innovation project by financing the proof-of-concept stage. Funded by the Auvergne-Rhône-Alpes Region, EasyPOC provides access to key CEA technologies in the fields of digital technology, health and energy.

Media contact / Investor relations:

Aelyon

Valentine Boivin

+33 1 75 77 54 65

roctool@aelium.fr