Press Release

Thursday 29th of February 2024

Roctool presents a new technology at JEC World, Paris (5-7 March)

Introducing the Groundbreaking R-IDS™ Technology for Superior Performance and Unmatched Energy Efficiency

Demonstration of Roctool’s R-IDS™ in collaboration with JEC World and its “Live Demonstration” zone

Prepare to be amazed at JEC World in Paris next week as Roctool unveils its latest technology: the R-IDS™ (Roctool Induction Dynamic Saver).

With 20 years’ experience in induction technology for tooling, Roctool confirms that this new technology is set to redefine standards in the composites industry, combining unrivaled performance with significant energy savings. This heated platen technology is dedicated to compression and to the molding of thermoset and thermoplastic composites, which completes Roctool existing technology arsenal.

Where Innovation Meets Live Demonstration:

-

Catch us in Action: Hall 6, T72 for live demos with leading material providers.

-

Visit Our Stand: Hall 6, U90 to discuss with our team and learn more

In response to growing demand and an increasingly energy-conscious market, Roctool’s R-IDS™ is being presented at the JEC World Composites show.

In response to growing demand and an increasingly energy-conscious market, Roctool’s R-IDS™ is being presented at the JEC World Composites show.

This innovative approach to heated platens, infused with the unique Roctool touch, enables users to move from a development stage to final production like never before.

Drawing from an extensive patent portfolio and knowhow, Roctool’s R-IDS™ introduces a dynamic new standard in composites market.

This marks a bold leap towards mass production in composite parts, guaranteeing first-rate performance.

Outperforming Traditional Heating Methods:

-

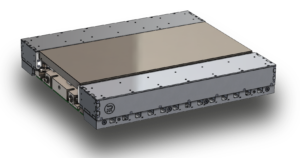

Superior to Oil Heating and Electrical Cartridges: R-IDS™ has been meticulously designed to surpass the limitations of traditional oil heating and electrical cartridges, offering unmatched efficiency and performance.

-

Adaptable, Efficient, Versatile: Compatible with molds and inserts made from aluminum, steel, to nickel-based alloys.

-

Dynamic Temperature Management: Achieve rapid, uniform heating with induction technology (400°C+), optimizing cycle times and reduced energy consumption.

-

Innovation Made Simple: Effortless heating and cooling of molds, streamlining thermal analysis.

R-IDS™ is not just an advanced technology; it’s about making this technology accessible, reducing time to market, and providing a sustainable, long-term investment that integrates smoothly into existing workflows.

Outperforming traditional heating methods, R-IDS™ adapts to small parts as well as large, multi-m² parts, offering the ability to reach high temperatures while reducing development costs, without compromising on reliability or safety

A Comprehensive Solution: R-IDS™ comes as a full package, offering the heated platen, the heating elements, the generators to the cooling units, ensuring a seamless, turnkey solution.

Don’t Miss the Live Event: Join Roctool and their material partners as they showcase unique combinations of tooling and material combinations. Be there to witness R-IDS™ in action.

Roctool LIVE Demonstrations:

Tuesday March 5th: 10:00 to 10:30am / 12:15 to 12:45pm / 4:15 to 4:45pm

Wednesday March 6th: 10:00 to 10:30am / 12:15 to 12:45pm / 4:15 to 4:45pm

Thursday March 7th: 11:30am to midday

OFFICIAL PARTNERS

Click here to view the press release in English

Cliquez ici pour Français

Read more about R-IDS™ here