This partnership advances specialized solutions for textured materials. Standex Engraving Mold-Tech and Roctool SA sign a global commercial and technical agreement A new partnership in the molding industry will now offer advanced, specialized solutions for textured surfaces and materials.

Standex Engraving Mold-Tech, a world leader in custom textures and tooling services has signed a commercial and technical agreement with Roctool, a global leader of heating and cooling molding technologies. This agreement enables these partners to leverage their technical expertise not only on current texture designs, but also to develop solutions previously unattainable, especially in the area of functional textures and other innovations. “This agreement aligns with our growth strategy and promotes our one partner vision. The combined technologies will allow us to offer expanded solutions to our customers and drive new market opportunities,” said Jim Hooven, President of Standex Engraving Mold-Tech.

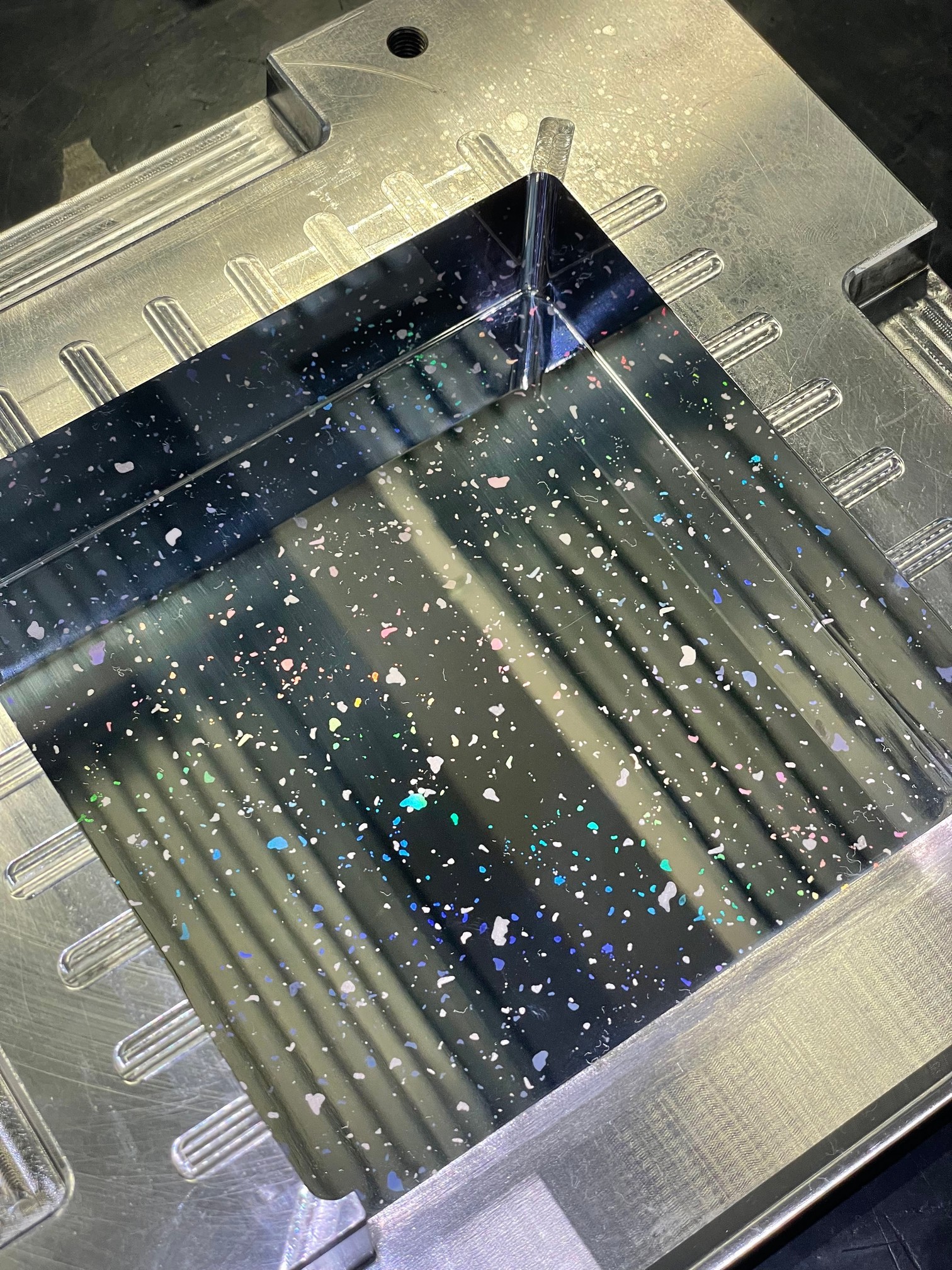

Mold laser engraved by Standex for the K-show 2022 in Dusseldorf, Germany

Standex Engraving Mold-Tech and Roctool have collaborated on customer solutions for years and have now formalized their partnership to offer a unique value proposition for the automotive, plastics, technology, textile, construction, solar energy, packaging, and a variety of consumer goods markets. Combining global texturing capabilities from Standex Engraving Mold-Tech and Roctool heat and cooling technology conveniently offers access to global expertise, support and technology, all in one step. “We are extremely happy to formalize our partnership with Standex Engraving Mold-Tech. The combination of our services is a game changer for the industry and will help us to deploy our technology to brands and their suppliers around the world,” said Mathieu Boulanger, Roctool’s Chief Executive Officer. Roctool heat and cool technologies have now been integrated into two of Standex Engraving Mold-Tech facilities to support customer projects globally, with more expansions to come.

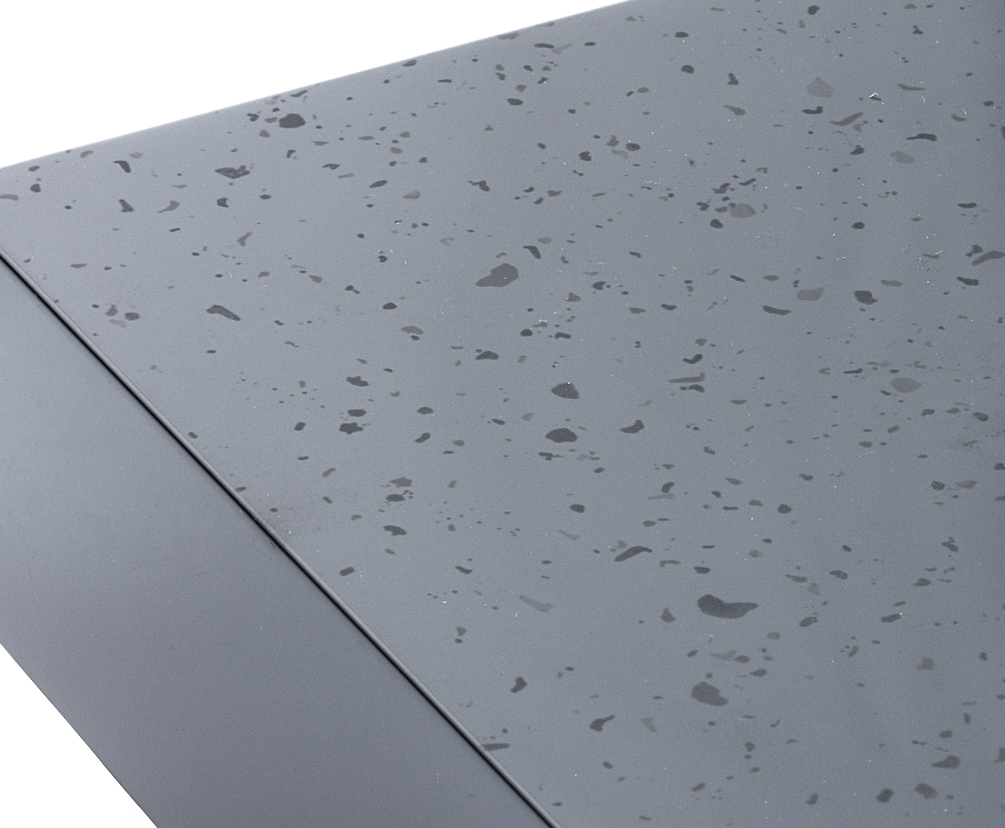

Part molded by Roctool during the K-show 2022 in Dusseldorf, Germany

Standex Engraving Mold-Tech creates custom textures on tooling to enhance the beauty and function of a wide range of consumer goods and automotive products we all use every day. We offer a One Partner solution, managing every step of the process from texture design and engraving, to preparing the tool for manufacturing with worry-free results. We make it easy for our customers by offering a full range of services: Architexture Design Studio, Laser, Chemical and Hybrid Engraving; Soft Trim Tooling; Roll-Tech and Tool Finishing. Standex Engraving Mold-Tech has become the global leader by offering our services from more than 40 locations, supporting Original Equipment Manufacturers (OEM), Tier 1 suppliers, mold makers and product designers. We focus on continuing to meet the needs of an evolving marketplace by offering experienced craftsmanship while investing in new technologies. Visit us on https://www.mold-tech.com About Roctool: Roctool, specializes in rapid heat and cool technologies for plastic injection and composite molding. The processes developed by Roctool are in production in the following industries: automotive, electronics, consumer products, renewable energy, beauty packaging and medical. Roctool is an induction molding technology, working with plastic and composite including recycled materials. Roctool offers Engineering services, induction generators, tooling hardware and on-site support to manufacturers around the globe. Roctool technologies are well known for removing secondary operations which enable manufacturers to reduce the overall cost of the parts produced, as well as their environmental impact. Headquarters are found in Le Bourget-du-Lac (France), Roctool is present in the USA, China, Japan and Germany.

For more information: www.roctool.com