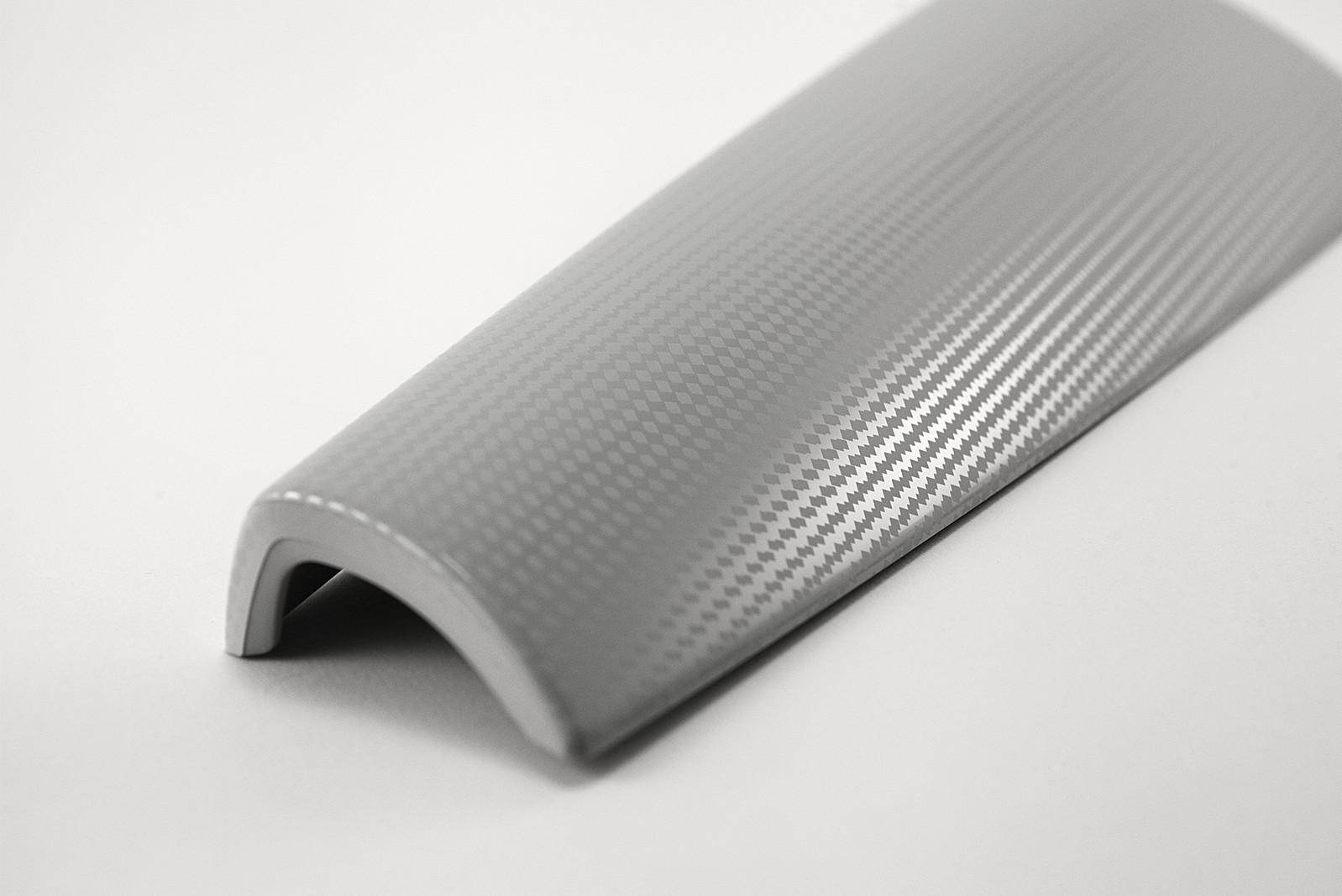

Textured Surfaces for MINI, Unique Interior Trim Parts

Interior trim parts without any secondary operations and still obtain a unique premium look with creative patterns.

How it all started

Our client target was to make different interior trim parts without any secondary operations and still obtain a unique premium look with creative patterns.

The combination of Roctool technology and laser texturing techniques in the mold made it possible.

Achievements

MATT & GLOSS WITH DIFFERENT COLORS

Roctool worked alongside Sole for BMW/Mini to ensure the textured surfaces in the dash trim were reaching a HD Plastics™ level. By using Roctool technology and unique laser texturing techniques, the surface quality of combined grain and mat, feels smooth and nice to touch, which adds a personalized element to the car interior.

NO PAINT, NO FILM, NO SECONDARY OPERATIONS

Using textured surface, without film or paint, there is a major improvement compared to conventional methods. Hard to believe that the parts are not decorated after molding. Parts are made in one shot with a perfect replication of the texture directly on the part surface with no defects. Quality improvement and cost saving at the same time.

ROCTOOL TECHNOLOGY

Heat & Cool system

ECO-MOLDING™

Industry

Stories

Automotive, Aerospace, Electronics, Beauty, Consumer Goods, Medical

Work

with Us

Feasibility Study, Engineering, Analysis & Tool Design, Components, Installation