R-IDS™

- A new standard for composite processing with high-performance heated platens.

- 1st step towards composite manufacturing in mass production

NEW TECHNOLOGY

Heated platens with a Roctool touch

Roctool now offers:

- A Dynamic temperature management thanks to induction heating

- Savings in energy consumption, cycle time

- Supporting clients from initial development steps to final manufacturing

- Quick development

- Long term investment

- Molding inserts are compatible with steel, aluminium and nickel alloy

Download R-IDS Flyer 2024

KEY ADVANTAGES

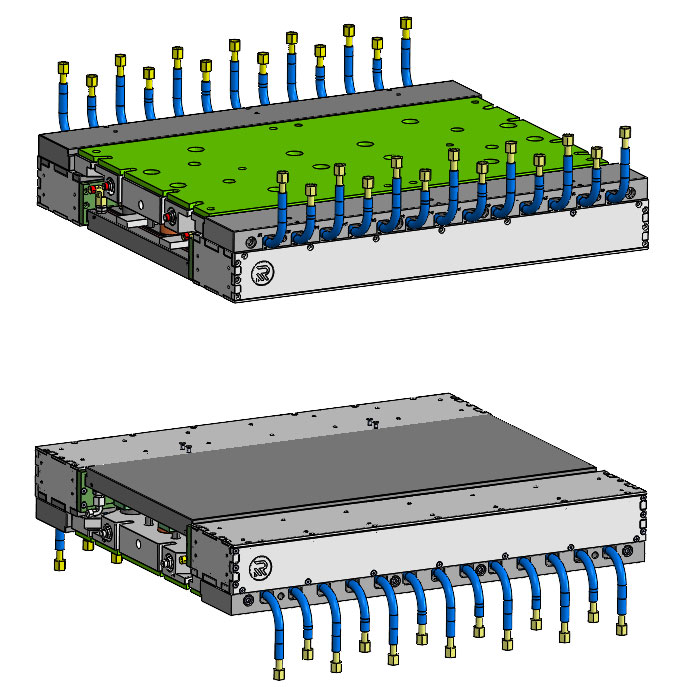

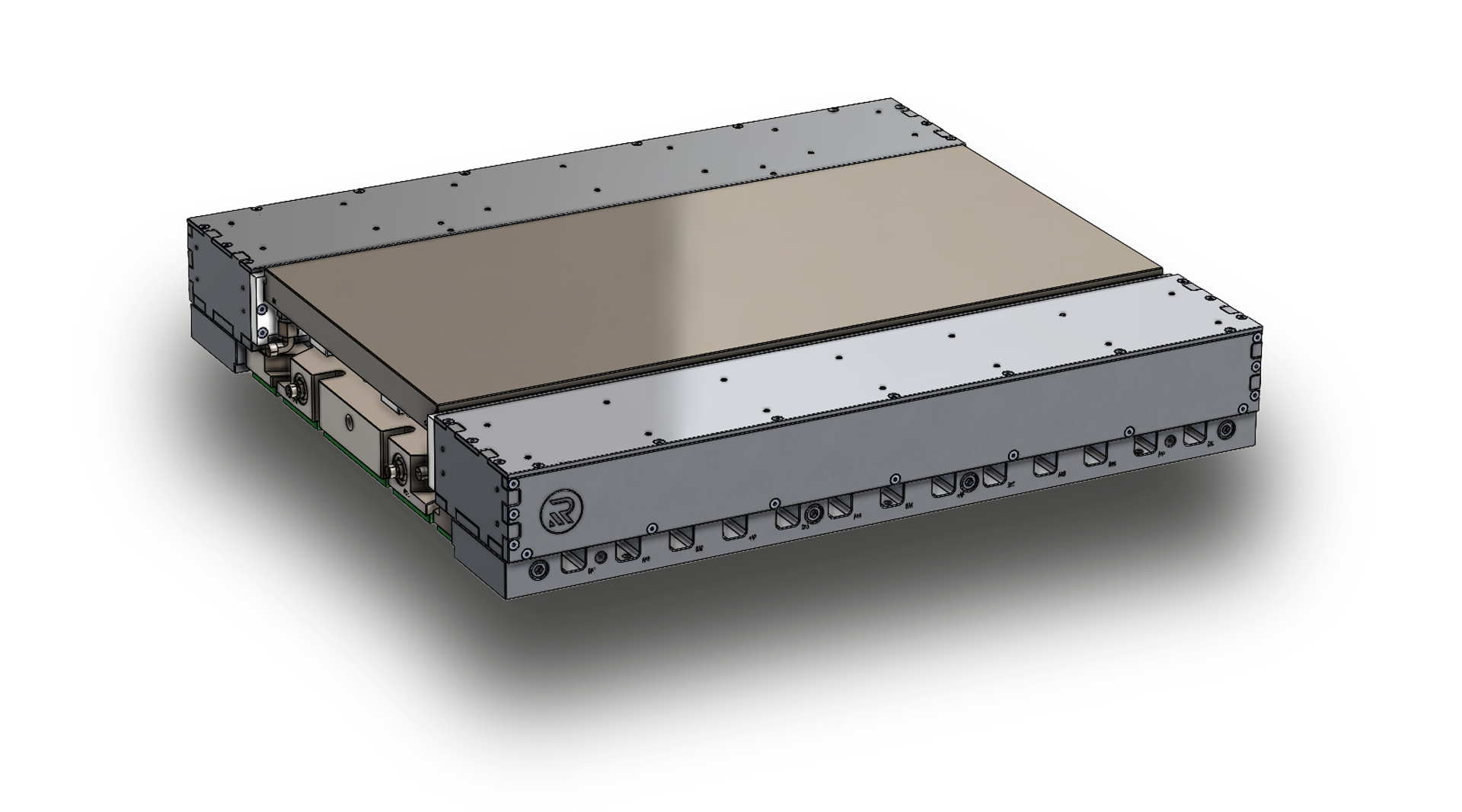

Using Roctool’s patent portfolio we designed versatile heat & cool platens

- Heated platen

- High temperature (400°C+)

- Optimised energy

- Reliable & safe

- Small, large surfaces & multi m² parts

- Versatile process

- Consistent cycle time

- Long term investment

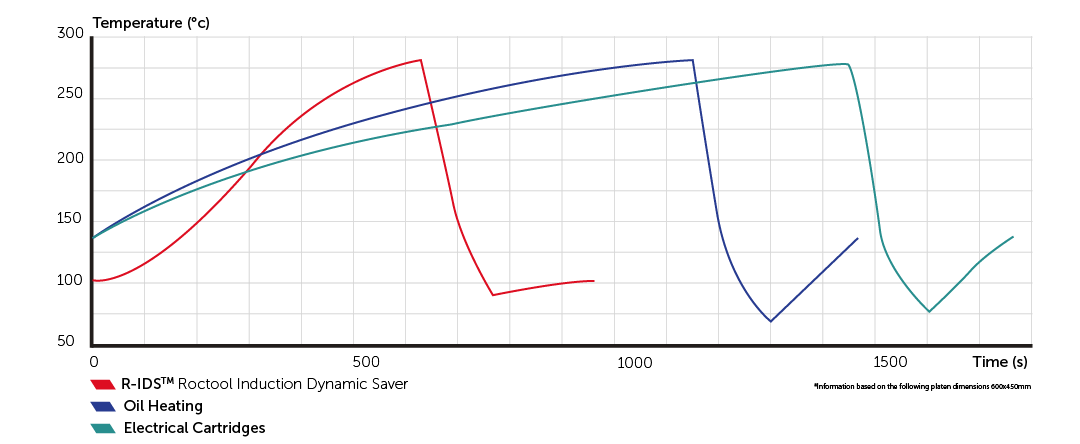

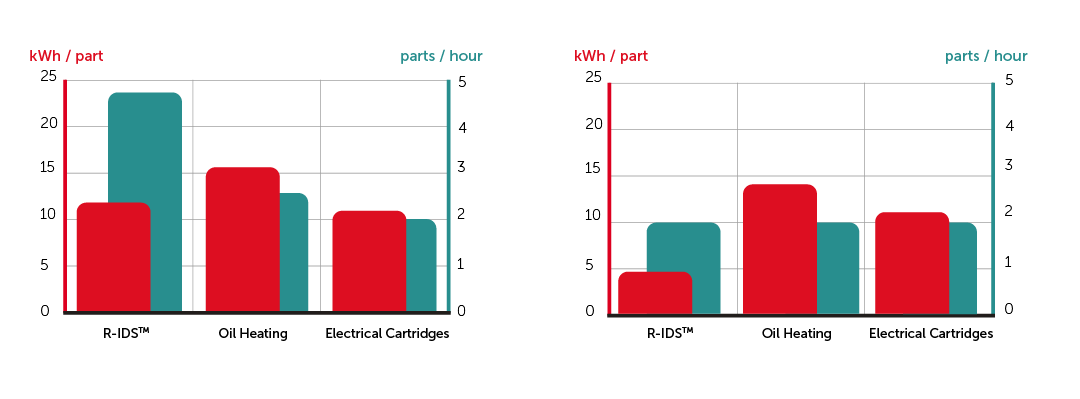

Comparisons

BETWEEN OIL HEATING & ELECTRICAL CARTRIDGES

CYCLE TIME

Using R-IDS™ heating time can be reduced by half or a third

Resulting cycle time

Same cycle time

R-IDS™

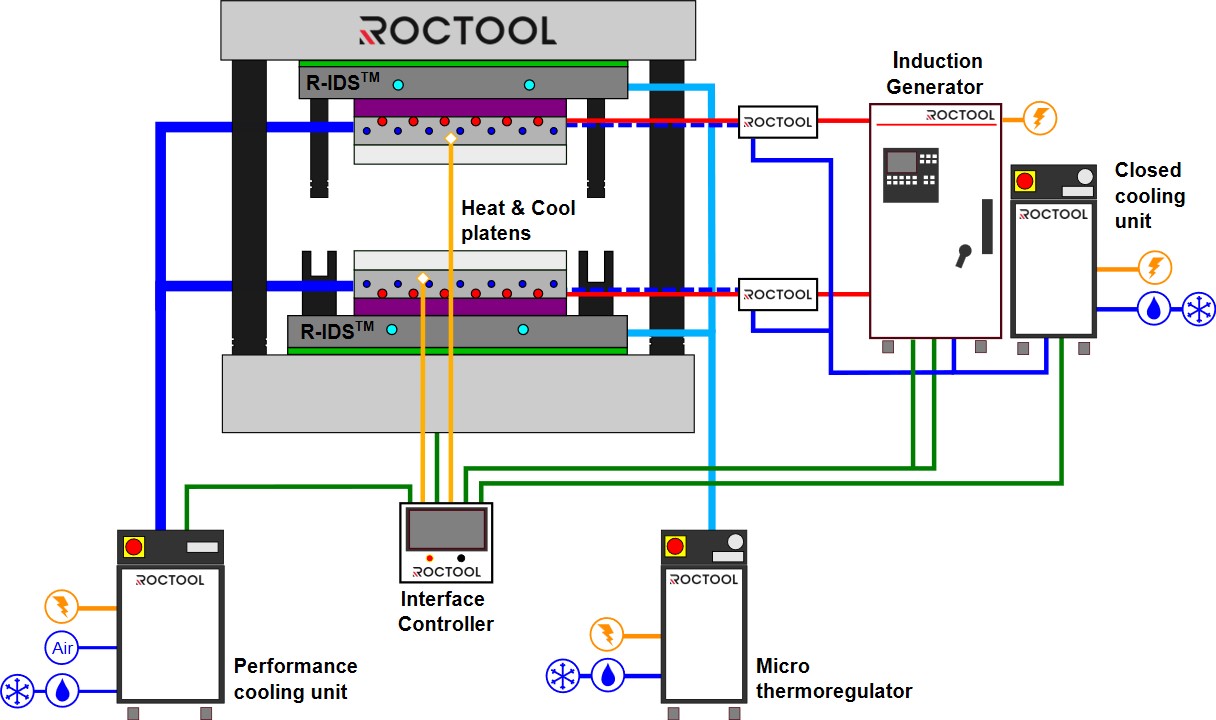

Full Package

Turnkey solution

- Heated platens

- Heating elements

- Induction generator

- Cooling units

- Interface controller

- Thermoregulated unit

- Any other peripheral equipment needed

We’re ready to work on your project.

Send us a short brief for the production of your part, we’ll answer you back within the next 48 hours.

ROCTOOL TECHNOLOGY

Heat & Cool system

ECO-MOLDING™

Industry

Stories

Automotive, Aerospace, Electronics, Beauty, Consumer Goods, Medical

Work

with Us

Feasibility Study, Engineering, Analysis & Tool Design, Components, Installation